PIM, the data heart of road surfacing

Never before have road users and governments had so many demands to make of our roads. By using Pavement Information Modelling (PIM) software, contractors and authorities have more insight into the road surfacing process and collect valuable data. If a road that has now been renewed needs to be tackled again in ten or twenty years' time, a large part of the data for a material passport will be uniformly available.

Thomas Vermeer, Ballast Nedam's pavement materials technologist: "We use PIM on the projects, in the laboratories at the asphalt plants and in the offices." In the Netherlands, PIM is the largest portal that supports the road paving process with technical data and schedules.

Structure and standardisation

The road construction process consists of several steps, with different parties constantly taking part. In the tender phase, the teams enter the structures they want, the work they have to carry out and the specific mixtures available for this purpose. The four-eye principle ensures that this data is checked and supplemented. During processing, the mixtures of asphalt, bound foundation, supplied unbound foundation materials or sand are processed and laid. The planning process of the work execution, from request to approval, is also in PIM.

Product owner Sietse Robroch: "PIM provides structure and standardisation in the data. The software that Ballast Nedam and, for example, Strukton and BAM use, is basically exactly the same. That is why all parties can work well together in every phase without having to have an insight into each other's data. Ownership, control and keeping data at the source are the characteristics that enable us to support the process properly. In addition, each party has its own database, which we periodically have ethically hacked to check the security.

With PIM, there is structure and standardisation in the data.

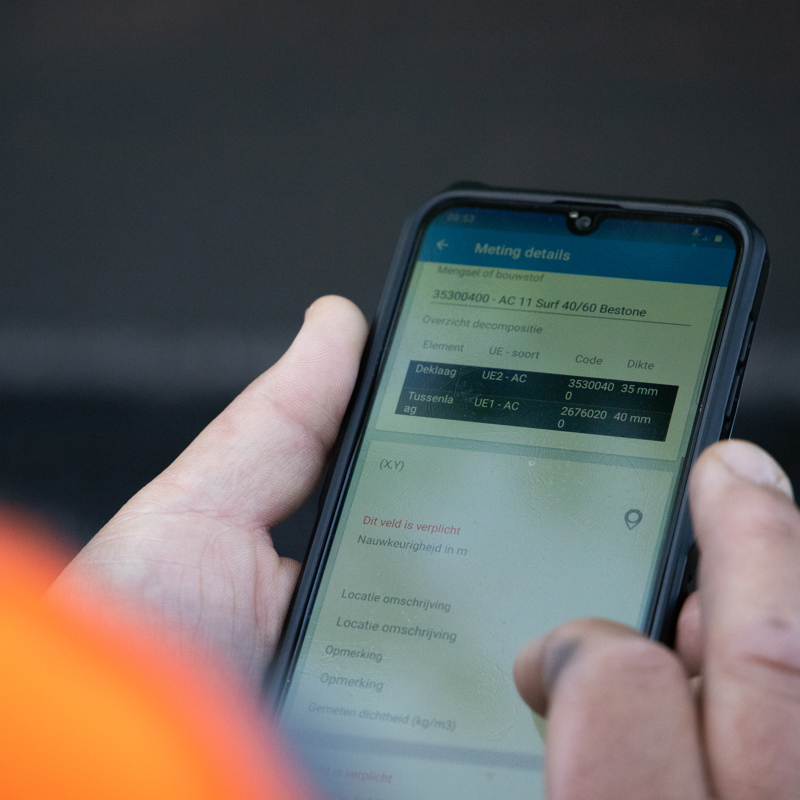

PIM app

PIM is an online application that can also be accessed with an app. The PIM app is intended to record in-situ data of, for example, measurements with a phone or tablet. At the moment, mainly technologists use the app for their quality checks. All outdoor activities and relevant data - measurements, drill core, location - can be collected in the PIM app. But also the asphalt contractors can see exactly which asphalt requests they have for the coming period and keep an eye on the status of delivery.

Deployment of PIM at Ballast Nedam

Ballast Nedam uses PIM in all phases of the construction process. Thomas: "In the tender phase, we can calculate with the right mixtures in PIM. There is now a verification procedure that was often skipped in the past: can't we do it more efficiently, better, cheaper? We also make full use of PIM when applying for asphalt. We can order from all Ballast Nedam asphalt plants and from 75% of the Dutch asphalt plants using our PIM account."

"We also use the PIM app for the inspections that we carry out as a quality service. Our work planners now always have the latest versions of the DOP, CE and the abbreviated report available to provide to the client. Now that Ballast Nedam has been entering data for over a year, we can better analyse the quality we actually deliver and the lead times of certain processes. Are we using all the asphalt we ordered or do we need less? Are there certain problems with processing in certain weather conditions? Why are there deviations in the road surfacing? We can then react to that."

Now that Ballast Nedam has been entering data for over a year, we are better able to analyse it

Making data transparent

In PIM, the cross-section of the road pavement and a plane in GIS (software that allows you to analyse geographical data) are linked. It also contains the exact location of the drill cores - and the corresponding surveys. Just like the building materials of the mixture (linked via an asphalt mixture), the asphalt plant that produced it and which quarry the crushed stone came from.

Sietse: "This gives us an enormous database. This is relevant from a sustainability point of view, for current projects and for the maintenance phase: demolition, adjustments or renewing layers. The next step is to make the data available to clients and to the industry in order to be able to analyse it across companies and projects. Where are there problems, what trends do we see? What variables can we control so that the asphalt lasts longer? By using PIM, you have more insight into the project and you collect valuable data. If a road that has now been renewed needs to be tackled again in ten or twenty years' time, a large part of the data for a materials passport is uniformly available."