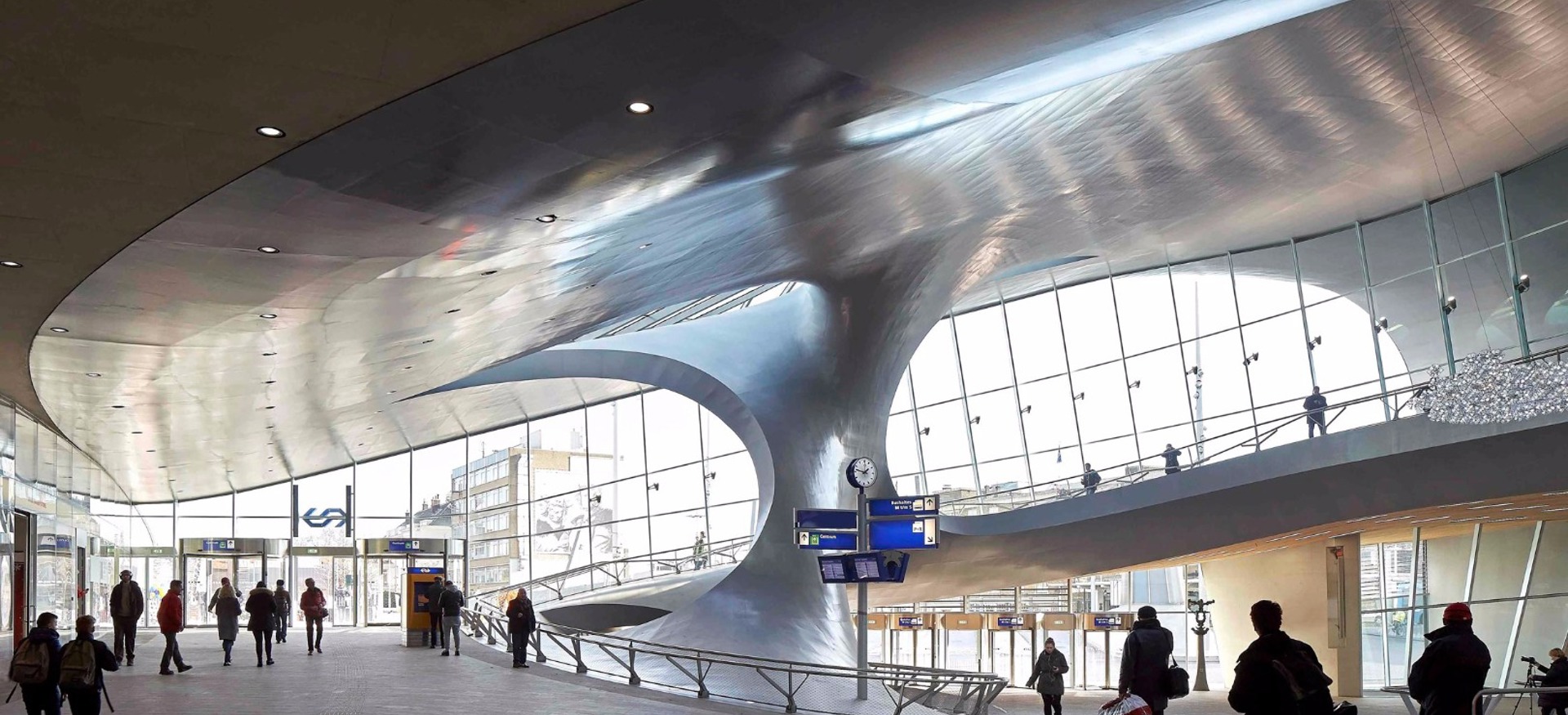

Arnhem Centraal Public Transport Terminal

This project involved building a transfer hall linking the train station’s passenger tunnel to the bus station, bicycle parking, taxi rank and car park. We also built new office space with a gross floor area of 2,500 m². The public transport terminal was the final element of the Arnhem Centraal master plan, which had been under way in Arnhem city centre since 2000. A particularly special aspect of this project was UNStudio’s organic design, which was largely constructed using steel to achieve the unique curves.

-

1,400 concrete panels

-

2.500 m2 new office space

Innovative ability

The steel shapes could be prefabricated, allowing certain risks to be reduced and controlled more easily. Using steel also made the structure much lighter. Concrete, the material originally envisaged, was used for part of the building. On the roof, for example, 1,400 concrete panels give the building an unusual appearance. Microbeton® developed a special, deformable mould system to allow the light, but double-curved, roof panels to be manufactured quickly and efficiently. This led to the project being honoured with the 2015 Dutch Concrete Award and the 2016 European Concrete Award.