Ports

Cruise ports: a destination for countless tourists, every year

As with most projects, the process starts with thorough research. We outsource this research so that we get independent and reliable results from specialists. Based on this research, we determine the implementation. If we are dealing with rock bottom, we will drill. If the soil is soft clay or peat, as in the Netherlands, then we lift.

During these activities, we make sure that we do not create clouds of sand underwater as that would affect flora and fauna. We shield the dredging work with bubble screens with a pipe under water. We put a compressor on it, through which the bubbles are led upwards. As a result, the impact remains within the zone in which we are working.

Deep under water

Preserving coral is paramount. That is why we start with careful inventory. Can we perhaps move the plans up a few kilometres? If that is not possible, our divers remove the coral and put it in a safe and suitable area. We make sure to keep the volume of coral the same and pay attention to light, depth and temperature.

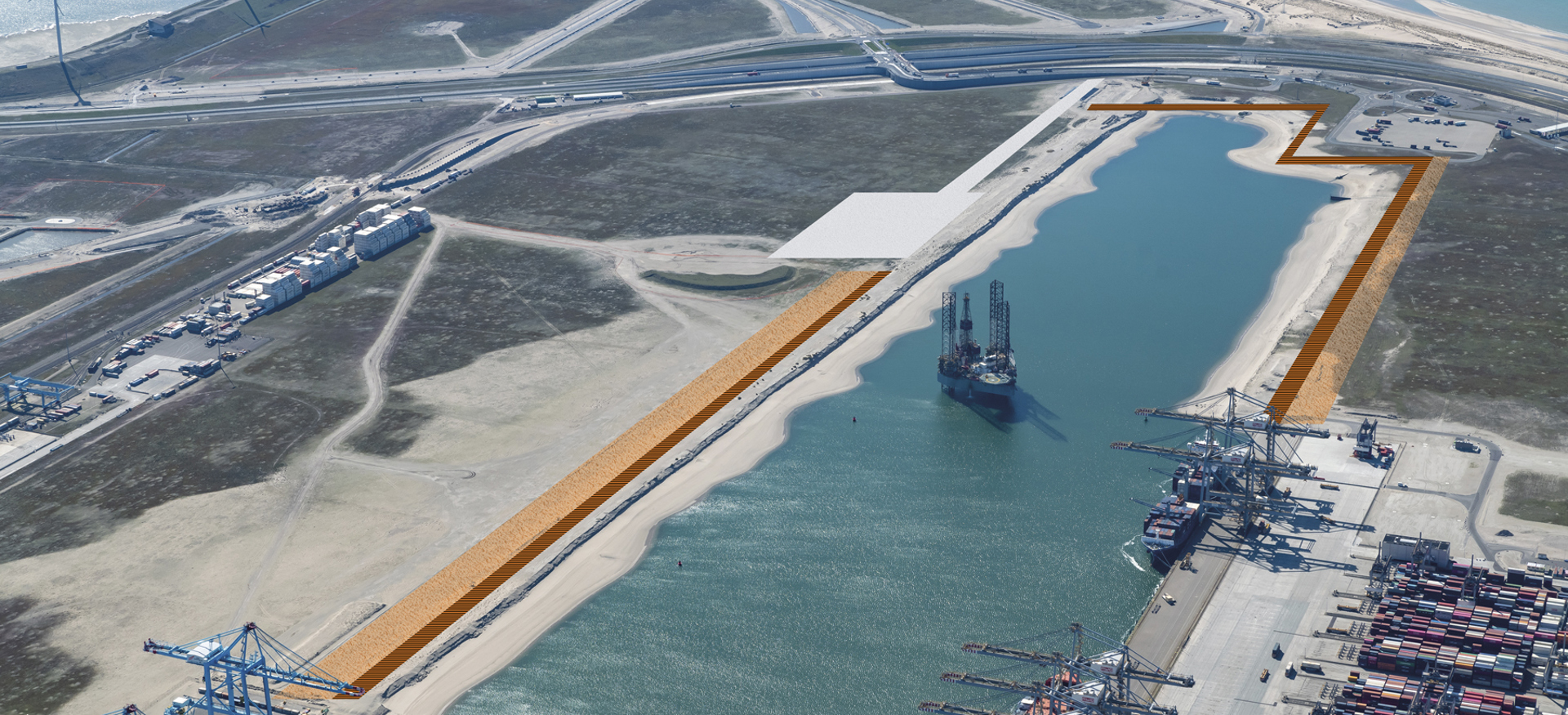

Container ports: a completely different line of work

In container ports, the operational processes of the container terminals must be able to continue uninterrupted. That is why we limit the nuisance to the environment by transporting building materials largely by water.

In addition, sustainability is a top priority. We reduce emissions during execution by using Hydrotreated Vegetable Oil (HVO). This fuel type has a CO2 reduction of 89 per cent compared to diesel and has lower emissions of emissions such as particulate matter, nitrogen and sulphur.

Smart quay walls

At the Princess Amalia Harbour in Rotterdam, this leads to the use of 'smart quay walls'. This works as follows: When a container ship moors, many forces are exerted on the bollards and fender systems to which the ship is attached via mooring lines. We can measure these movements, just like the deformations of the structures. This leads to data that the client can then use to further develop or expand the port.

What this yields? Perhaps we can build the quays with thinner or lighter steel and concrete. This saves money, transport and material, and it leads to sustainable choices for an efficient port.