Construction of Princess Amalia Harbour quays

Rotterdam wants to remain Europe's largest port.To achieve this, the port must be prepared to smoothly guide the world's largest container ships into port. Commissioned by the Port of Rotterdam Authority and in collaboration with trusted partners HOCHTIEF and Van Oord, Ballast Nedam has completed the expansion of the Prinses Amaliahaven: an ingenious feat of engineering involving 2.4 kilometers of smart quay wall extension.

-

2.4 kilometres of intelligent quay wall

-

1,825 metres deep-sea quays

-

360 metres earth retaining walls

2.4 kilometres of new quay wall

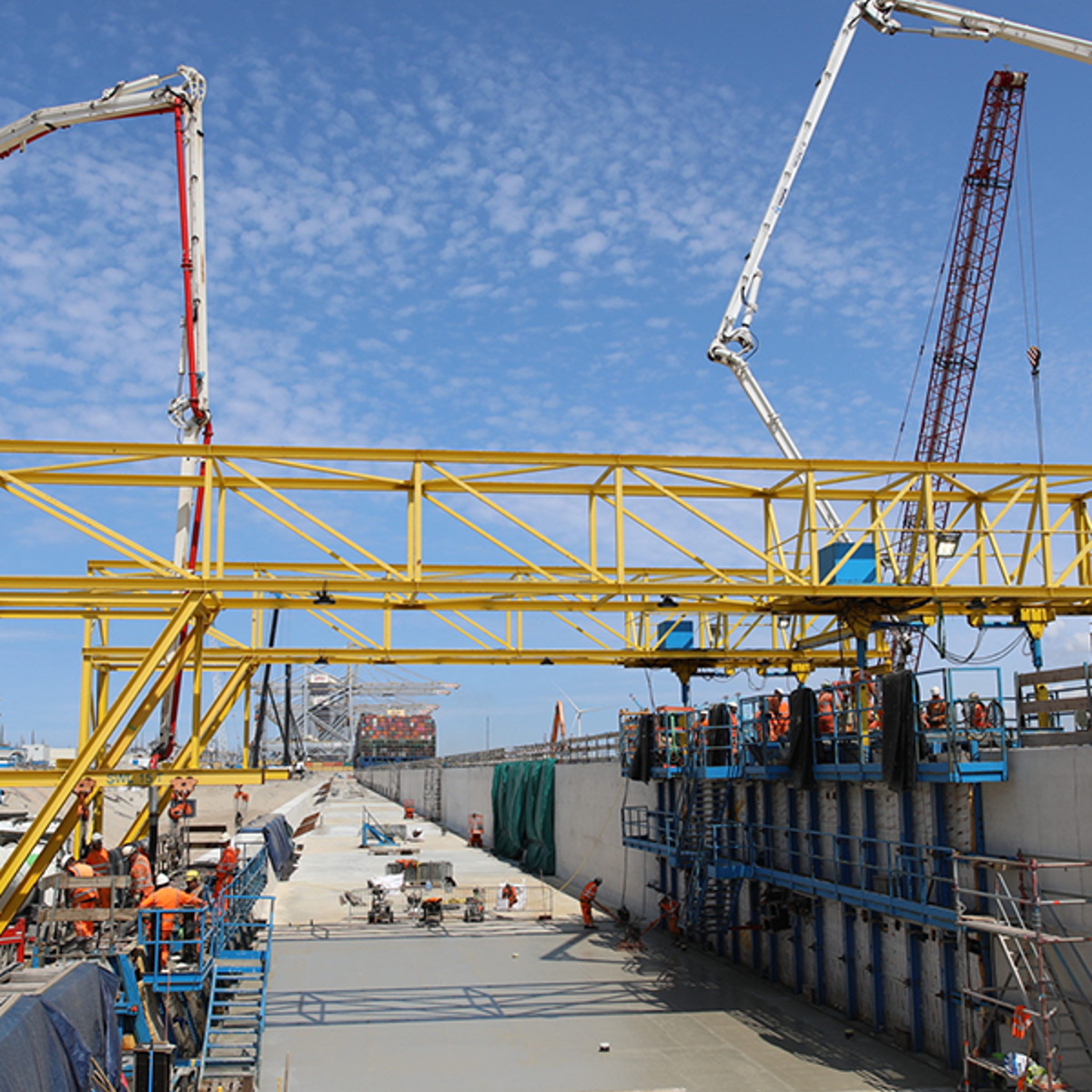

Every day, around 356 sea-going and inland vessels sail in and out of the port of Rotterdam. That number is growing, partly due to increasing e-commerce, and the ships are getting bigger and bigger. Thanks to the new deep-sea and inland waterway quays in the Prinses Amaliahaven, container terminals now have the space to develop further and prepare for the loading and unloading of more and larger ships. This expansion will enable the port to handle an additional 4 million TEU per year, strengthening Rotterdam's competitive position. The new construction is located on both sides of the port and consists of 1,825 meters of deep-sea quay, 160 meters of inland shipping quays, and 360 meters of earthworks. The deep-sea quay has a retaining height of almost 30 meters and is constructed from a combination wall with Ø1420 mm tubular piles and sheet piling in between. A rear crane track, founded on vibro piles, runs along the entire length for the container cranes.

An innovative quay wall

It is not only the size of the quay wall that makes this project special. The Prinses Amaliahaven also stands out from other construction projects in terms of technology. The quay wall is equipped with sensors that monitor forces and deformations. This allows technicians to monitor the movements of the quay wall when ships moor. This information helps the Port of Rotterdam Authority with the maintenance of this quay wall and the design of future projects. These smart sensors reduce the need for physical inspections. In addition, smart bollards have been installed to measure the tensile force of mooring lines, and the quay has been prepared for shore power.

Less nuisance, less emissions

In line with the Rotterdam mentality, we work in a practical, effective, and sustainable manner. We limited disruption by transporting building materials, such as aggregates (such as sand and gravel) for the concrete and the steel tubular piles and sheet piles, by water. This reduced traffic congestion on the roads, while the container terminal processes continued as usual. Our construction machines ran on Hydrotreated Vegetable Oil (HVO), which reduces CO₂ emissions by 90% compared to regular diesel. We worked with electric cranes and used green electricity. In addition, we used a fully electric concrete mixer with a battery capacity of 600 kWh, which saved approximately 300 kg of CO₂ emissions per day. Van Oord used an LNG hopper dredger and an underwater drone (ROV) for inspections, reducing physical diving activities by 80%. ECOncrete blocks were installed at two locations to serve as artificial reefs to stimulate underwater biodiversity. To further optimize logistics and limit disruption, a dedicated concrete plant was set up on site.

Working safely together

In a mega-project such as the Prinses Amaliahaven—where many logistics flows converge and which is also located on the water—safety was given extra emphasis. Already in the tendering phase, we developed a conceptual plan in which we separated transport flows by land and water and did not deliver any materials at all at certain times of the day. In this way, we guaranteed traffic safety: both on land and on water. After winning the tender, we further refined the measures. We created separate access roads for passenger and construction traffic, laid a separate footpath along the construction road, designed the construction roads to be clearly laid out, and enforced traffic rules for construction traffic. In addition, we used performance indicators to ensure tidy and well-organized work sites. In this way, we are contributing to a safe, future-proof port infrastructure that is ready for the next generation of shipping.

More information?

Sander Lefevre

Managing Director Ballast Nedam Infra Projects a.i.